CHRIS RAMSEY, WOODTURNER

SELECTED PHOTOS

Page One | Page Two | Page Three | Studio

Page Three

Legged Bowl Instructions

Turned and carved three-legged pieces can be challenging and are a lot of fun to make. The shape and design of a turned and carved piece can be changed on the fly and any changes in size, shape or design is welcomed. You allow yourself the opportunity to explore unlimited shapes, designs, leg styles, rim design, natural edge, manufactured rim, closed form, open form, big and tall or short and squatty forms. For this document I have turned a closed form natural edge three leg bowl.

The majority of the turning on this project is done using a ½” bowl gouge. I do use a ¼” detail gouge, a power sander, 80, 120, 180 and 220 grits sandpaper and CA glue. The carving disks used are the Holy Galahad 4 inch disks made by King Arthur Tools that mount to a 4 ½” grinder. King Arthur makes four different grit disks in two different profiles, however, you will only need item #47871, a flat coarse blue disk. I occasionally use a rotary tool like a Mastercarver or Fordom rotary carver and some carving burrs for finer detailed carving.

Select a fresh cut or “green” piece of wood for this project. A fresh cut piece of wood will be much easier to turn and you will not have to deal with dry cracked wood. This piece will be turned in a side grain orientation. Although this piece will be turned from a large maple burl, I have included several pictures of a piece of straight grain timber so you will have a complete understanding of how the log is cut and how the layout of the bowl is determined. I will also show how to balance the rim of the bowl so that the two highest points on the rim are on the same elevation and the two lowest points are on an equal elevation.

Figure 1

Look at the center of the log and notice the direction of the split or crack in the center or pith of the log. Stay a minimum of 1” to the outside of the center or pith of the tree and, using a straight edge, draw a line from bark edge to bark edge following the direction of the split. (Do the same thing on the other side of the split and you will have two bowl blanks.) If you cut to close to the pith make sure you turn away enough materials to get away from the pith or the bowl may crack during the drying process. Try to use the same measurements on each end of the blank from the top of the bark edge to the line drawn at the bottom near the split or crack. It may be helpful to draw a line from the center of the pith toward the outside of the tree to line up the growth rings once the log has been cut in half as in Figure 1. This will help to make the bowl appear very well balanced.

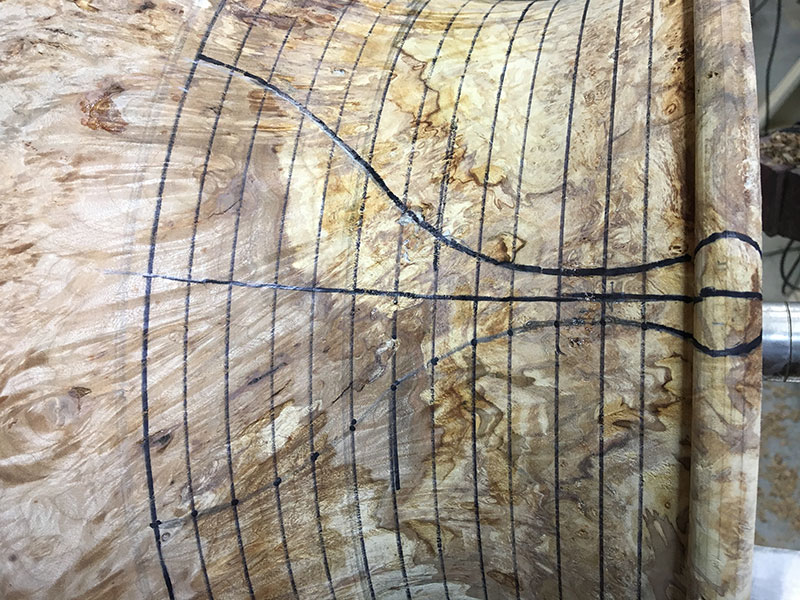

Figure 2

Cut the log following the previously drawn lines as in figure 2.

Figure 3

After the log has been cut in half transfer the mark from the pith of the tree on the end grain ends to the side grain ends on the flat cut surface. Draw a line connecting the two marks as pictured in Figure 3.

Figure 4

Using a compass put the point of the compass in the center of the line and draw a circle for the diameter of the bowl as in Figure 4. Using a chainsaw remove the corners and excess of the wood outside the circle to round the blank. Once the blank has been rounded with the chainsaw you can proceed with the straight grain blank the same as with a piece of burl that I have selected for this project pictured below.

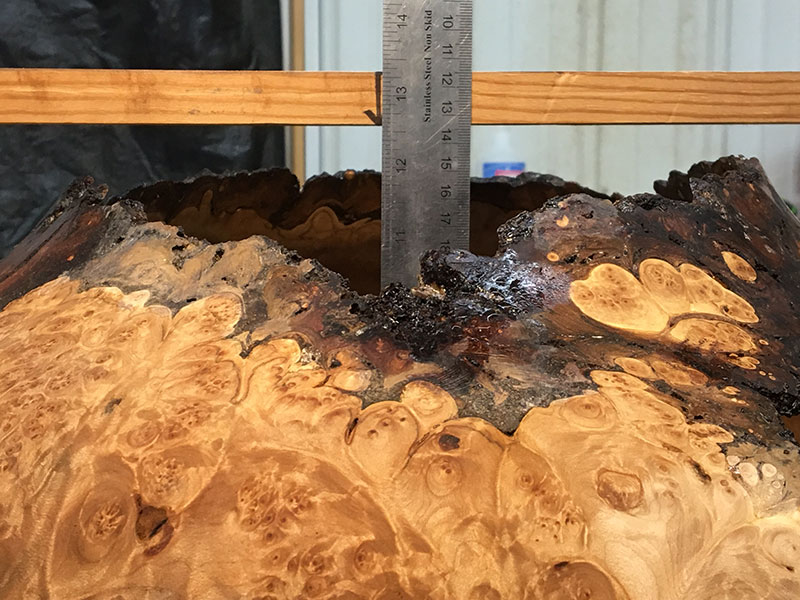

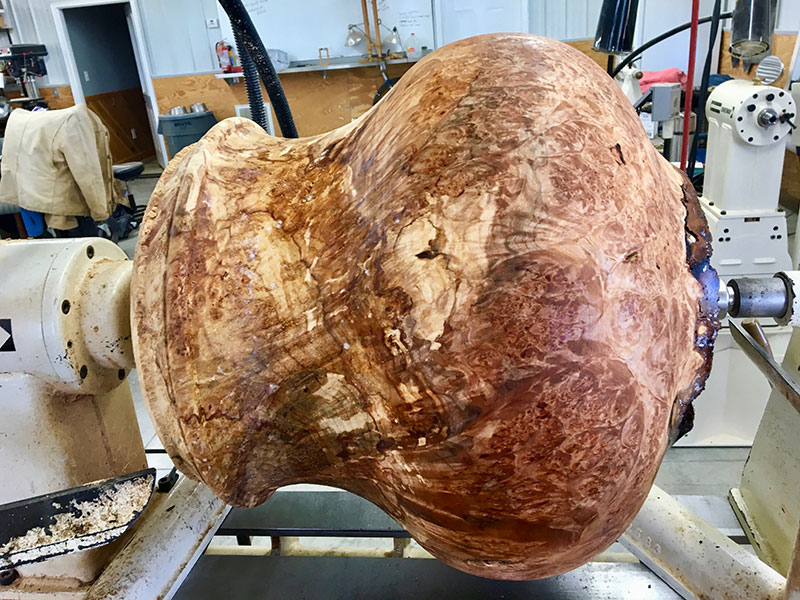

This is the maple burl I started with.

Pictured above is the cut blank from the burl measuring 24 inches in diameter by 24 inches tall.

Mount the blank on the lathe between centers using a two-prong spur drive in the direction of the grain. If you are turning straight grain timber keep the spur drive on the previously drawn line on the pith as in Figure 3. As long as the spur is on the line you will end up with an elliptical shape in the center of the bottom of the bowl. Moving the spur off of the line will move the elliptical shape to the side of the bottom of the bowl which is much less pleasing to the eyes and less desirable.

Now you will balance the high points of the natural edge rim. Keep the spur in the center of the blank and on the line and reposition the bark surface at the tailstock side so that the two high points (end grain only) are on the same level when it is rotated. I use the tool rest and measure from the tool rest to the bark surface then adjust as needed. Once the two high points are on the same level you will balance the two low points (side grain only) and get them as close to the same level as possible. Before turning you will need to stabilize the bark surface with CA glue. I glued the entire surface because I cored several bowls out of the blank. Now you are ready to turn the outside shape.

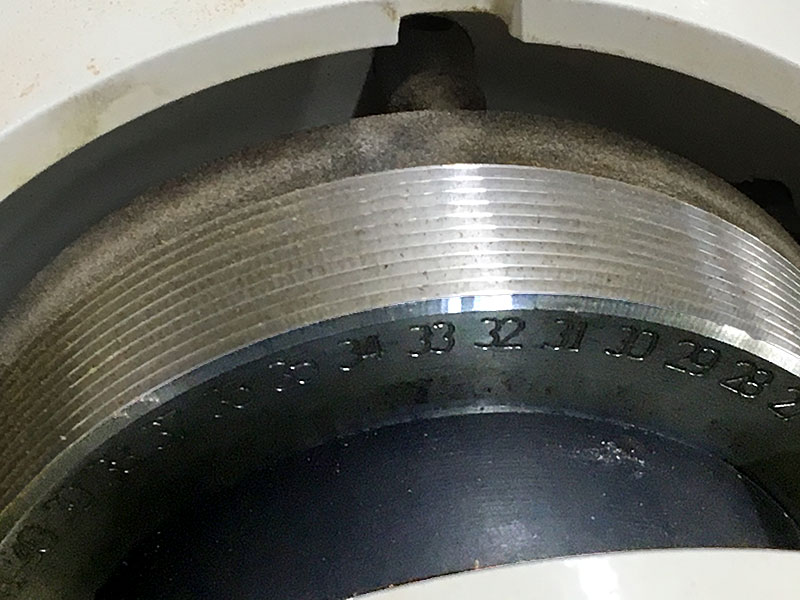

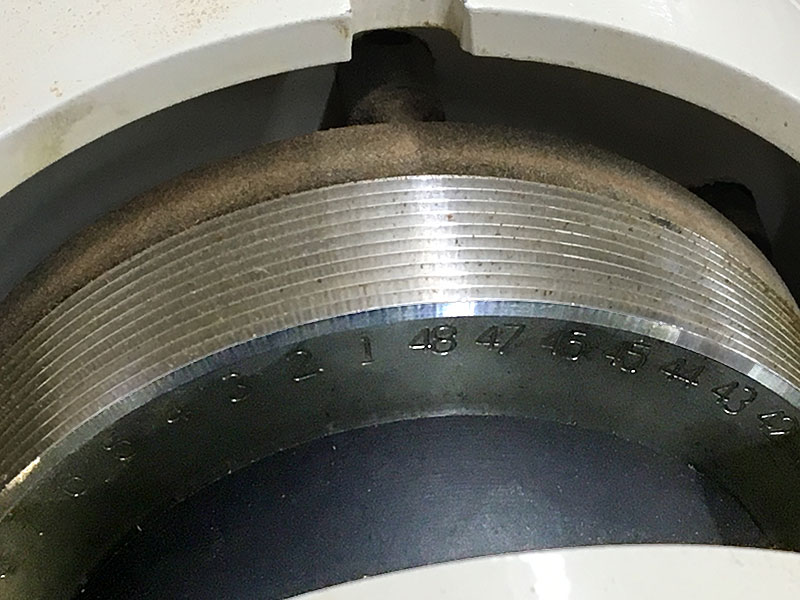

Rough the blank until it is round. Turn the bottom of the blank flat to accommodate a faceplate. I used a 6 inch faceplate and drew a 6 inch circle on the base while the blank was spinning to help align the faceplate. Remove the blank from the lathe, cut off the nub where the spur was and secure the faceplate to the blank. Mount the blank back on the lathe without the use of the tailstock and round the blank so there is no wobble and the blank runs true. Turn out the hole the live center originally made when roughing the blank then bring the tailstock back for support. Now you can increase speed and establish the outside shape of the piece.

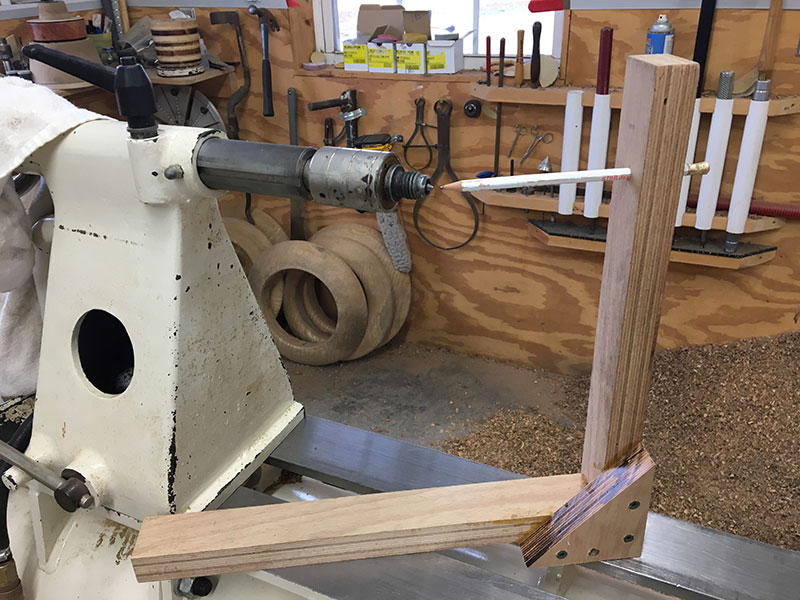

After turning the outside shape use CA glue on the outside bark edge of the natural edge to stabilize the outside of the bark rim. On this piece the rim was closed inward excessively for a beautiful yet challenging closed form bowl. I incorporated the leg design into the continuous flowing form and added a small bump out foot at the bottom of the leg design. Now that the outside shape has been established and the bark and outside surface have been stabilized with CA glue, I cored 4 natural edge bowls from the closed form bowl. A center steady was used to keep vibration to a minimum while coring.

Now that the bowl has been cored the hollowing can begin using a ½ inch bowl gouge. Hollow out the inside of the bowl working from the bark edge downward. Be sure to keep the flute of the bowl gouge facing three O’clock and only make push cuts until you have turned below the bark edge. A pull cut can blow the bark off of the piece even after it has been glued. After hollowing down to below the bark on the inside, stop the lathe and glue the inside of the bark edge of the bowl. Now that the top, outside and inside of the bark edge have been stabilized with CA glue the rest of the hollowing can Continue.

Continue hollowing the bowl to where you would like the top of the legs to begin on the side of the bowl. I draw a line on the exterior of the bowl to mark the location of the top of the legs and another line where the bottom of the bowl will be as pictured below.